400 MLD Desalination Plant, Chennai

Strengthening India’s Coastal Water Security

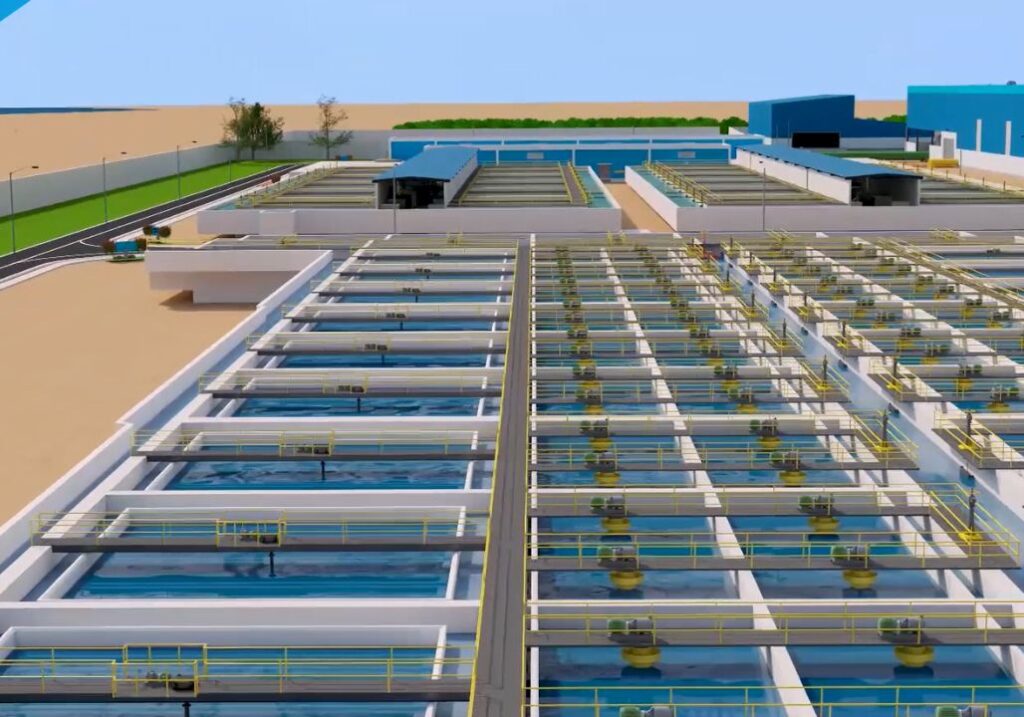

The 400 MLD Desalination Plant in Chennai, India, represents one of South East Asia’s largest and most advanced seawater desalination projects. Executed by WABAG in joint venture with Metito Overseas Limited for the Chennai Metropolitan Water Supply and Sewerage Board (CMWSSB), this Sea Water Reverse Osmosis Plant is a landmark initiative designed to reinforce Chennai’s long-term water resilience.

Funded by the Japan International Cooperation Agency (JICA), the project adopts state-of-the-art desalination technology to convert seawater into potable water for millions of residents. Once operational, it will contribute to nearly 70% of Chennai’s desalinated water production, establishing the city as the Desalination Capital of India and setting new benchmarks among global Water Desalination Companies.

A Breakthrough in Urban Water Sustainability

The 400 MLD Desalination Plant is being implemented on a Design-Build-Operate (DBO) basis and is poised to deliver 400,000 m³/day of high-quality drinking water. This large-scale Sea Water Reverse Osmosis Plant will cater to the southern parts of Chennai, addressing the region’s chronic water scarcity and dependence on monsoon rainfall.

Combining robust engineering with energy-efficient operations, the facility showcases WABAG’s proven expertise in designing large, sustainable infrastructure that meets the dual goals of environmental conservation and urban water security.

Scope of Desalination Plant

Comprehensive Design, Engineering, Procurement, Construction, Installation, Testing, and Commissioning of a 400,000 m³/day Desalination Plant, including seawater intake and transmission systems.

Technologies involved in SWRO Desalination Plant

- Lamella Clarifiers and Dissolved Air Flotation (DAF) for pre-treatment.

- Gravity Dual Media Filtration for fine purification.

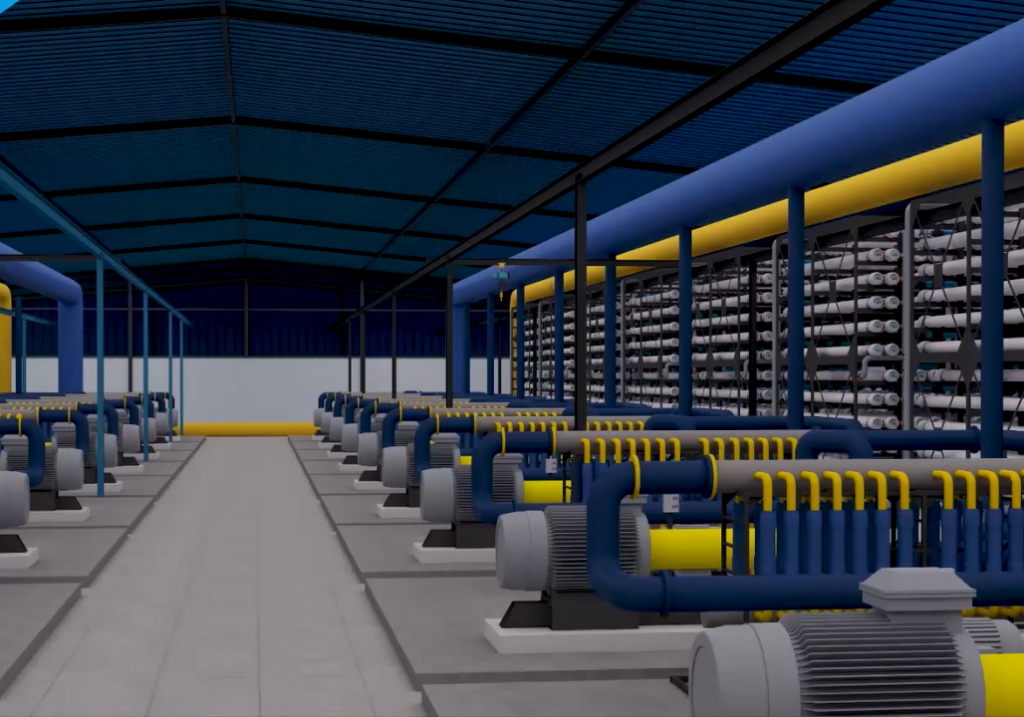

- Two-pass Reverse Osmosis (RO) for desalination and re-mineralization.

- Automation and control systems ensuring operational reliability.

This integration of modern technologies ensures high efficiency, low energy consumption, and consistently safe drinking water output.

Engineering Excellence and Capacity

The Desalination Plant is designed with advanced membrane systems and energy recovery devices that enhance efficiency and reduce the overall carbon footprint. With an installed capacity of 400,000 m³/day, it will be one of the largest Sea Water Reverse Osmosis Plants in Asia.

Its 20-year operation and maintenance framework ensures continuous performance, positioning WABAG among the most trusted Water Desalination Companies globally.

Environmental and Social Impact

The 400 MLD Desalination Plant will play a pivotal role in transforming Chennai’s water landscape:

- Reliable Water Supply: Provides safe drinking water for nearly 750,000 m³/day of desalinated output, covering South Chennai’s population.

- Reduced Water Stress: Lessens dependence on freshwater reservoirs and rainfall.

- Sustainability: Incorporates energy-efficient systems for long-term ecological balance.

- Urban Growth: Strengthens Chennai’s position as a model for coastal water management in India.

Chennai Sea Water Reverse Osmosis Plant – A New Milestone for Asia

The 400 MLD Desalination Plant in Chennai exemplifies how advanced desalination engineering can secure sustainable urban growth. As one of the largest Sea Water Reverse Osmosis Plants in the region, it underlines WABAG’s leadership among Water Desalination Companies, combining innovation, scale, and sustainability.

This Desalination Plant will not only redefine Chennai’s water future but also serve as a global benchmark for large-scale, climate-resilient water infrastructure.