Client

Reliance Industries Ltd

Location

Dahej, Gujarat, India

Capacity

43,200 m³/day RO permeate (expandable to 57,600 m³/day)

Industrial Effluent Treatment Facility Strengthening Water Sustainability for the Oil & Gas Sector

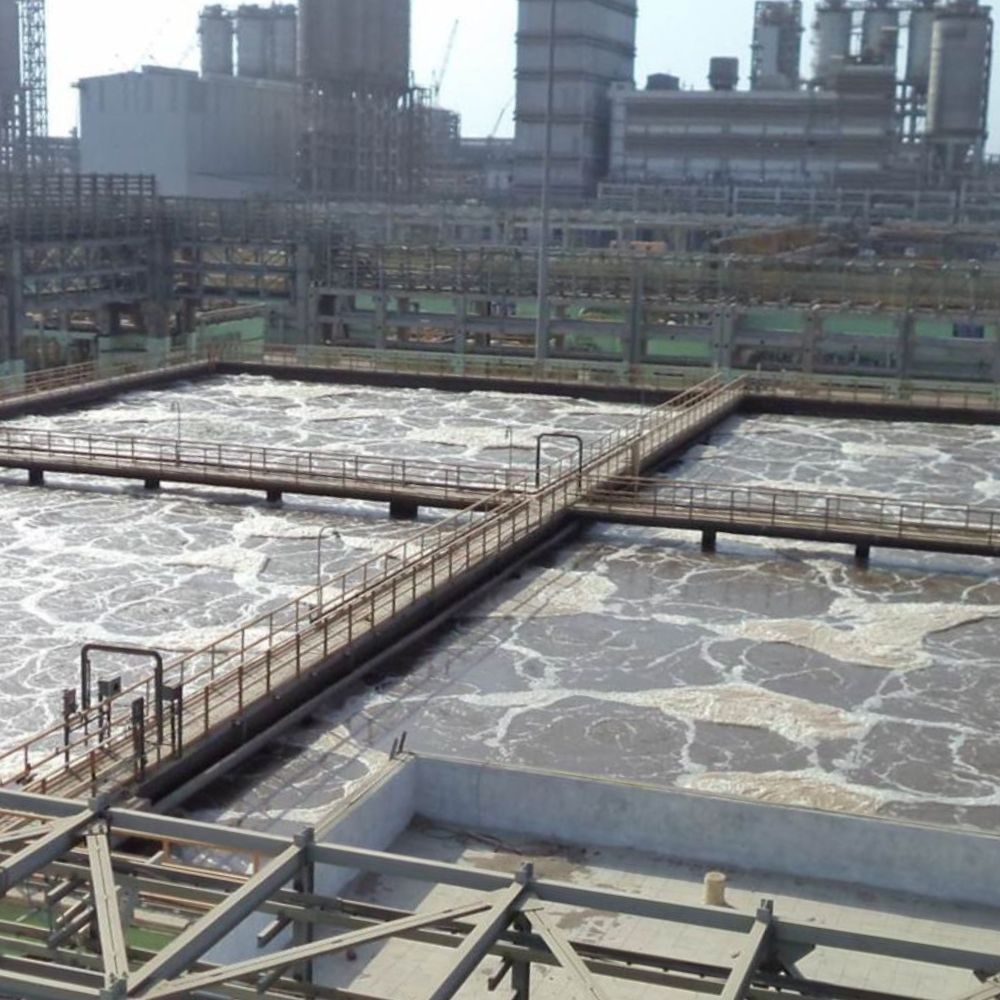

The industrial effluent treatment plant at the Reliance Industries Dahej complex plays a pivotal role in enhancing water sustainability for one of India’s largest petrochemical hubs. Delivered under the Design-Build-Operate model, the plant treats PTA and PET effluents using a combination of anaerobic and aerobic biological technologies followed by ultrafiltration and reverse osmosis to generate high-quality reclaim water for industrial reuse.

High-Performance Wastewater Treatment and Advanced Membrane Technology

The facility integrates a multi-stage treatment scheme combining UASB reactors, MARAPUR-MBR® technology, ultrafiltration and reverse osmosis. This treatment pathway ensures robust performance against variable industrial loads and delivers high-purity permeate suitable for process reuse, significantly lowering freshwater dependency for the petrochemical operations.

Water Recycle and Reuse for Industrial Sustainability

The reclaimed water generated at this facility directly substitutes fresh process water at the Dahej complex, closing the loop on industrial water consumption. By treating and reusing petrochemical effluents, the plant supports a circular economy model for the Oil & Gas sector, improves water resilience and reduces discharge into natural water bodies.

Biogas Recovery and Energy-Optimised Operations

A key differentiator of this industrial effluent treatment solution is the integration of sludge-to-energy conversion. The anaerobic process generates biogas that is recovered through gas holders and drying systems and utilised in CHP units to supplement plant utilities. This significantly lowers operational power demand and enhances the long-term viability of the treatment facility.

Comprehensive DBO Scope for Industrial Effluent Treatment

The project scope included design, engineering, installation, testing, commissioning and demonstration of performance for a high-efficiency multi-module effluent treatment and water reclamation system. Following DBO delivery, WABAG undertook 36 months of O&M responsibility to ensure process stability under full industrial load.

Treatment Process and Technology Integration

The treatment scheme includes:

- UASB reactors and MARAPUR-MBR® system

- Ultrafiltration and Reverse Osmosis

- Sludge thickening, drying and nutrient recovery

- Biogas recovery and CHP-based energy utilisation

This fully integrated process ensures reliable industrial wastewater recycling with consistent permeate quality for petrochemical reuse.

Impact – Circular Water Management for the Oil & Gas Industry

The facility recycles up to 43,200 m³/day of industrial wastewater, substantially reducing the Dahej complex’s dependence on external freshwater sources. By generating 63,000 m³/day of biogas, the plant meets approximately 40% of its power requirements, strengthening energy efficiency and operational sustainability. This project is recognised as a benchmark in circular industrial water reuse and reinforces WABAG’s position as a leading industrial wastewater recycling company in the Oil & Gas sector.